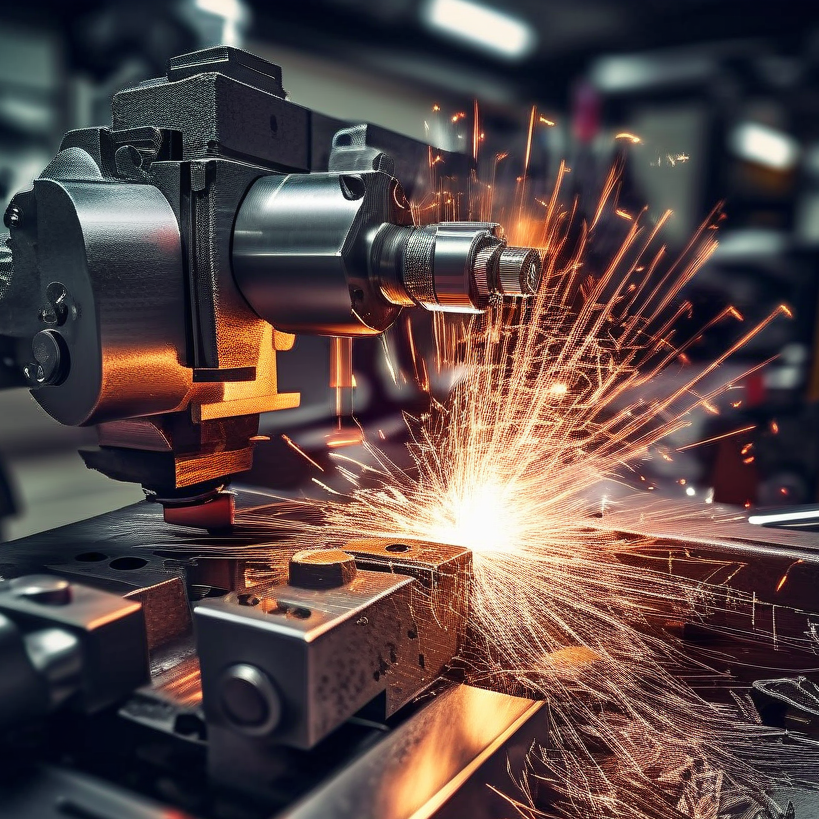

Precision Aluminum CNC Milling

Employing cutting-edge CNC technology to ensure precision and surface finish of aluminum parts. Suitable for complex shapes and fine details, offering custom services to meet specific requirements.

We are a professional CNC processing company concentrating on metal working and fabrication services. Our company has advanced CNC machining tools as well as an experienced technical team thereby enabling us to offer customers with the most precise and quality-assured metal working and manufacturing solutions. Our features are close attention to detail in producing goods and high quality; our strong side is that we take care of all customer demands by giving individual customization facilities in order to meet customer satisfaction.

In our company where quality is considered core in providing metalworking services encompassing CNC machining, it is considered indispensable. We always ensure that quality precedes all other things including revenues gained from sale. Therefore each stage from selecting inputs through controlling production stage up until testing final products is strictly monitored so that every item meets customer expectations.

Furthermore, there exists an all-round after-sales service system which enables us render timely technical support & solutions professionally hence instilling faith in buyers when choosing our metalworking firm.

Owing to different customer demands, we offer custom-made metal processing and fabrication solutions. As such we are able to develop personalized approaches for our clients based on an understanding of their process requirements, product specifications as well as features specific to CNC technique.

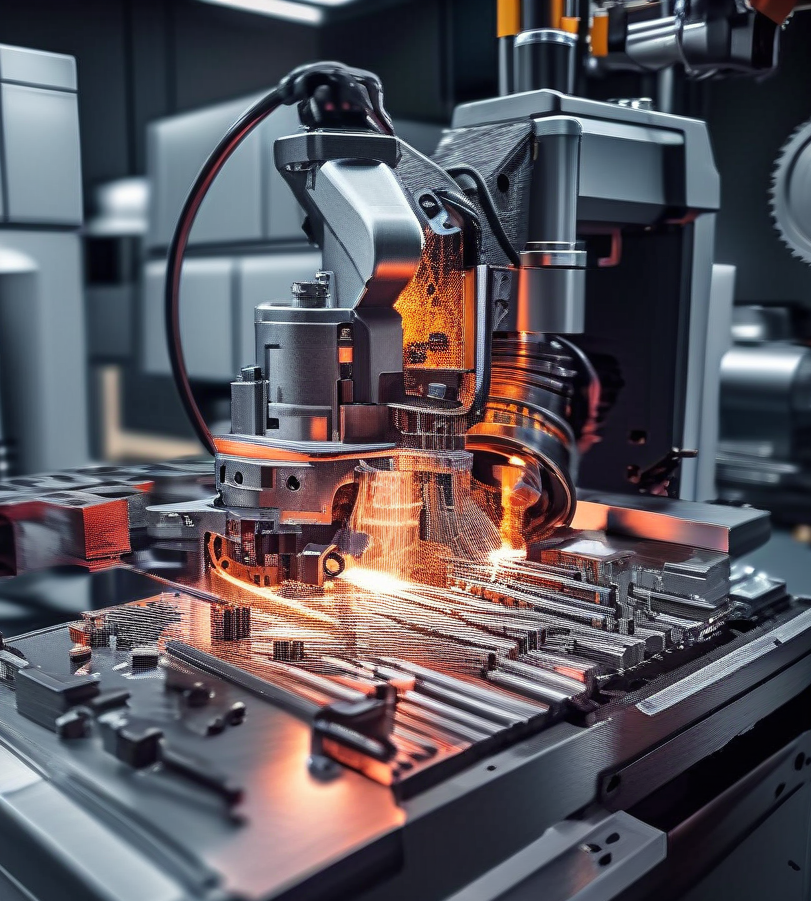

Through CNC machining technology we can undertake precision and high speed operations that suit different client’s needs whether they require large metallic structural parts or accurate fabrication of tiny mechanism components.

Within the field of CNC machining for metal manufacturing, our company has gained trust and appreciation from consumers owing to its professional technology and best quality services. We boast of an experienced team which is competent enough to provide customers with comprehensive CNC machining metal manufacturing services.

Our expertise covers technical advice, project development, manufacturing, etc., meeting all the customer’s needs through the help of our skilled personnel. Our choice means professionalism, trust and triumph. We are committed to putting customer first hence we will continue offering superior quality and highly efficient CNC processing metal fabrication solutions.

The accuracy and efficiency in the metalworking industry continue to become more demanding due to the rapid growth of the manufacturing industry. With its reliance on CNC machining technology, our company has supported its clients in upgrading their metal based products business.

By fine-tuning product quality through accurate CNC programming and automated production processes we can achieve refined metal material processing while increasing performance levels. Alternatively, this form of technology can lead to higher production output but at lower costs thereby creating more value for consumers.

Since its establishment in 2005, Jiayi Technology has been a leading manufacturer and supplier of a variety of ultra-fine quality precision sheet metal parts and CNC machined parts. As a company specializing in CNC machining, we are committed to providing the highest quality precision machining services such as CNC milling, turning, grinding and drilling. With advanced CNC machine equipment and an experienced technical team, we are able to ensure that the processing accuracy and quality of each part reaches the highest standards.

Our services cover a variety of industries, including aviation, automotive, medical, electronics, etc., providing customers with customized solutions to meet their special needs. We understand the importance of time, so we always strive to deliver high-quality products within the stipulated time to help customers maintain their production schedule.

Our goal is to become the world's leading CNC machining service provider through continuous technological innovation and excellent customer service. Whether you are looking for single piece prototyping or mass production, we look forward to working with you to create a better future.

Employing cutting-edge CNC technology to ensure precision and surface finish of aluminum parts. Suitable for complex shapes and fine details, offering custom services to meet specific requirements.

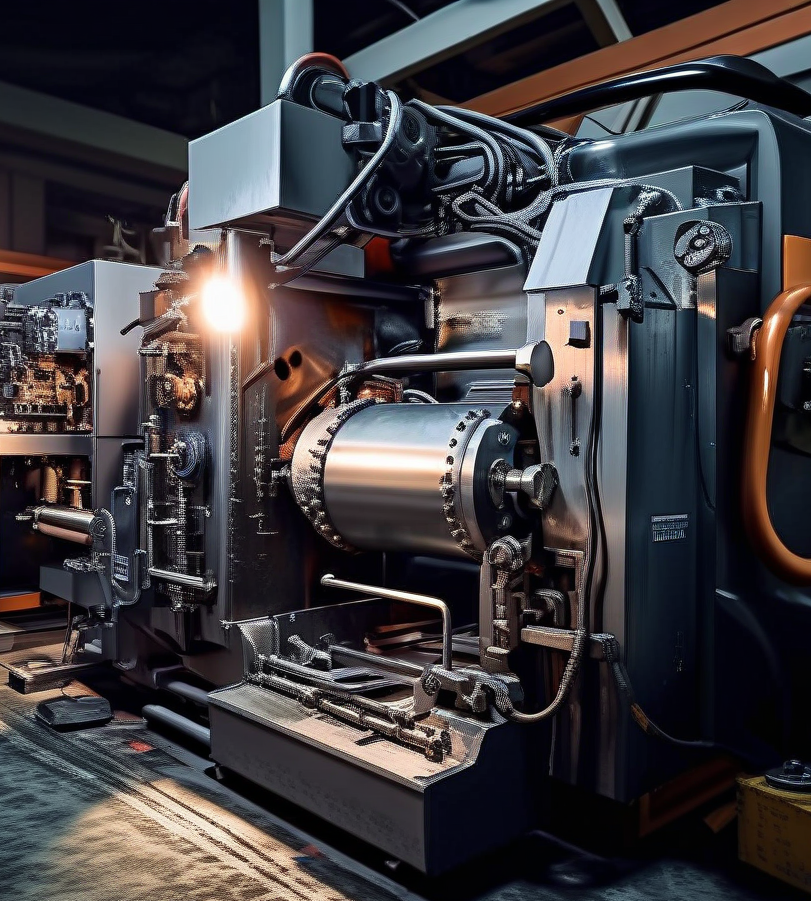

Utilizing advanced CNC lathes for turning, enhancing production efficiency and ensuring consistency in part dimensions. Suitable for a variety of materials, including metals and non-metals, guaranteeing durability and stability.

Specializing in high-precision and high-gloss grinding and polishing services to ensure parts meet strict tolerance requirements. Improving part performance and appearance to meet high-end manufacturing standards.

Offering fast and accurate CNC prototyping services, supporting rapid transition from concept design to finished product. Ideal for new product development and small batch production, accelerating market launch.

Yes, as a professional CNC machining company, we specialize in manufacturing precision metal structural parts made of various types of metals such as stainless steel, carbon steel, aluminum alloy, copper alloy etc. These include but are not limited to bending and welding processes for stainless steel, carbon steel, aluminum alloys, copper alloys and other materials used in making folded metal structure components. Stamping operations and CNC machining services.

We employ top-level CNC machine tools; apply advanced measurement tools and technology; strictly compliance with ISO quality management system to ensure precise quality control throughout the entire process. Meanwhile, we employ scientific processing flow and perfect test methods so that B-side clients have high accuracy and high-quality demand on metallic structural parts.

Surely, we have an experienced team comprising engineers who can undertake design customization as well as processing based on CAD drawings that you will give us. We can support many types of design files which will then be quickly transformed into a CNC programming language for efficient creation of products using metals.

Lean production is adopted which involves reasonable scheduling management combined with automation and CNC technology to improve production efficiency effectively reducing delivery cycle. On the other hand raw material cost is reduced through large-scale procurement while continuous improvement in the production process is aimed at eliminating waste thereby ensuring customer quality by managing their overall production costs.

Definitely .In addition to providing CNC metal processing services , we also offer one-stop solutions from the concept design, 3D modeling and prototype validation to mass production, partnering alongside multiple sectors within the industry. These encompass all stages from the idea of a product to its actual delivery in collaboration with our partners coming from diverse industries.