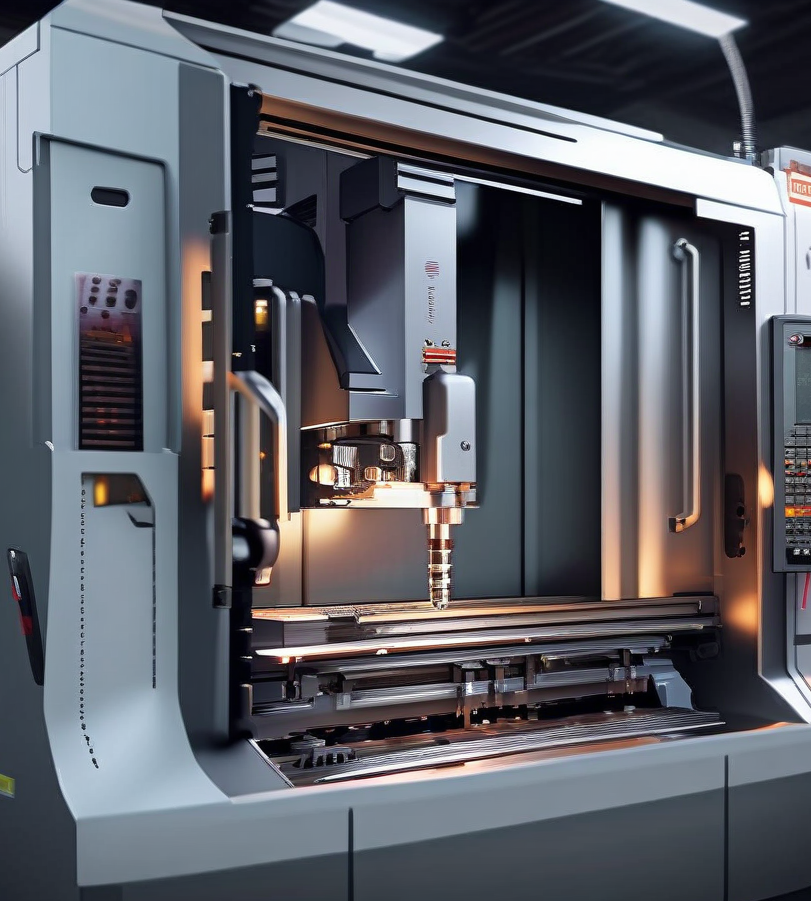

Precision Aluminum CNC Milling

Employing cutting-edge CNC technology to ensure precision and surface finish of aluminum parts. Suitable for complex shapes and fine details, offering custom services to meet specific requirements.

Diversified Materials Compatible with CNC Milling Machining Centers: Our customers enjoy a wide range of application options since it is not only traditional metals that our cnc milling services deal with but also engineering plastics, ceramics, composites among other non-metallic special materials which are especially useful in medical equipment or aerospace industry specialized part manufacturing.

Good machining can only be achieved through good CNC milling technologies which are the main building blocks of competitive edge for our company.

We possess proficiently skilled and experienced team of milling operators who have knowledge on different types of millings precisely determining processing parameters to ensure each product meets highest quality requirements. From material selection, tool selection or process control, everything must be perfect.

A variety of needs from clients make it necessary for our company to provide custom made CNC mill services. Our personalized plans are developed based on product characteristics and requirements as we understand the customer’s production needs best.

Flexible fast-precision batch production to mass production are attained using flexible CNC mill technology allowing customers save time and costs.

Our company is well known for its professional milling services in the field of CNC machining. We know better as a leader in the CNC machining industry that there is need to use CNC milling technology to produce highly accurate and efficient machinings.

With advanced CNC milling equipment and excellent milling techniques, we offer customers impeccable processing experience, meeting their diverse demands in different complex parts.

For technological upgradation in Cnc Machining , innovation is crucial. Our business keeps a close eye on latest developments concerning the cnc milling technology market where we actively seek new technologies, processes as well as equipment.

Continuous optimization of processes improves equipment performance while enhancing operational efficiencies, thus enabling us drive changes within Cnc Milling Technology. Additionally, we collaborate with colleges and universities together with other research organizations while working towards more sustainable development by developing more efficient eco-friendly cnc milling technology.

Since its establishment in 2005, Jiayi Technology has been a leading manufacturer and supplier of a variety of ultra-fine quality precision sheet metal parts and CNC machined parts. As a company specializing in CNC machining, we are committed to providing the highest quality precision machining services such as CNC milling, turning, grinding and drilling. With advanced CNC machine equipment and an experienced technical team, we are able to ensure that the processing accuracy and quality of each part reaches the highest standards.

Our services cover a variety of industries, including aviation, automotive, medical, electronics, etc., providing customers with customized solutions to meet their special needs. We understand the importance of time, so we always strive to deliver high-quality products within the stipulated time to help customers maintain their production schedule.

Our goal is to become the world's leading CNC machining service provider through continuous technological innovation and excellent customer service. Whether you are looking for single piece prototyping or mass production, we look forward to working with you to create a better future.

Employing cutting-edge CNC technology to ensure precision and surface finish of aluminum parts. Suitable for complex shapes and fine details, offering custom services to meet specific requirements.

Utilizing advanced CNC lathes for turning, enhancing production efficiency and ensuring consistency in part dimensions. Suitable for a variety of materials, including metals and non-metals, guaranteeing durability and stability.

Specializing in high-precision and high-gloss grinding and polishing services to ensure parts meet strict tolerance requirements. Improving part performance and appearance to meet high-end manufacturing standards.

Offering fast and accurate CNC prototyping services, supporting rapid transition from concept design to finished product. Ideal for new product development and small batch production, accelerating market launch.

The milling machine, which we have in our possession, has various specifications and is characterized by maximum processing size that varies from tens of millimeters to several meters depending on customer demands and the model used. So, we always select the most suitable production equipment for providing high-quality CNC milling services considering your part size and technical requirements.

Our CNC milling machine has a high-precision positioning system. Generally, we can achieve a processing accuracy of ±0.005mm to ±0.01mm. For some special applications and precision parts, it can be further improved through multiple processing and precision measurements. Improve accuracy and meet micron-level control requirements.

Of course we support it. We have extensive experience and expertise and are able to handle CNC milling operations on various materials, including but not limited to stainless steel, aluminum alloys, cast iron, copper alloys, titanium alloys and other difficult-to-cut materials. Suitable tools and tools can be selected according to the material characteristics. Processing strategies.

We implement a strict quality management system during the mass production process, including first article inspection, process monitoring, SPC statistical process control and other means. Each CNC milling machine is regularly calibrated and maintained, while utilizing advanced CAM software for precise programming, ensuring consistency and accuracy every time.

Absolutely. Our company is equipped with a multi-axis linkage CNC milling machine, which is capable of complex three-dimensional surface milling and five-axis linkage processing tasks. It is especially suitable for the processing of workpieces with complex geometric shapes and high precision requirements in aerospace, automotive parts, mold manufacturing and other industries. . Our team of engineers are proficient in advanced CAM programming technology and dynamic simulation to ensure efficient and accurate machining of complex workpieces.