- Overview

- Inquiry

- Related Products

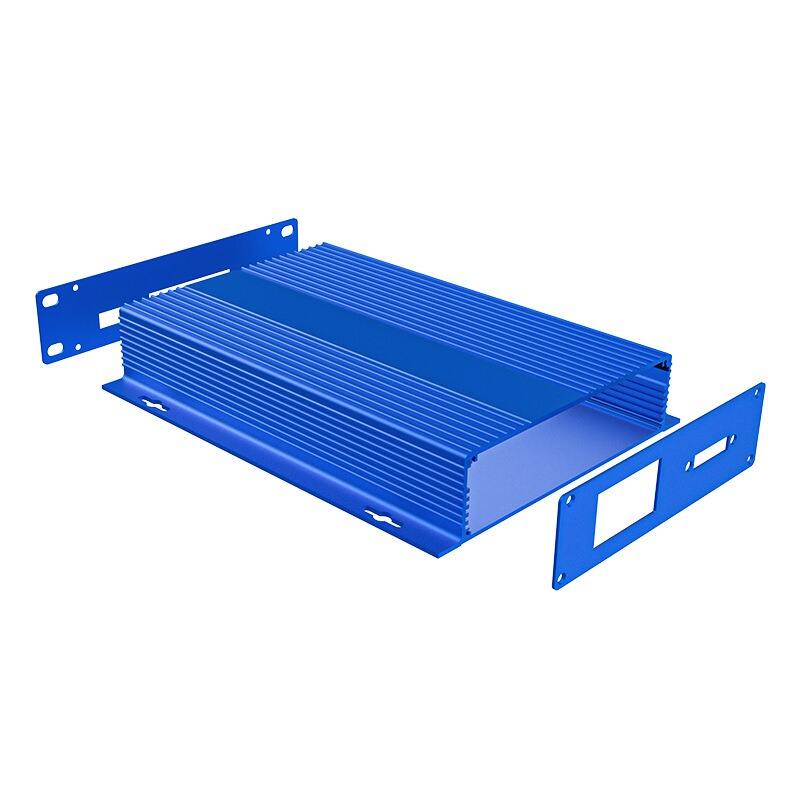

Customizing a metal gaming keyboard is not only about exterior design, but also a craft that integrates materials science, acoustic engineering, and personalized expression. It represents the pursuit from 'sufficient' to 'ultimate', providing players with unique competitive tools and desktop artworks.

1.Material characteristics

Aluminum alloy, the main body is made of 6063 aluminum

Surface treatment: anodizing process, sandblasting (180 mesh), presenting a delicate color card level

Brass is used for the weight part, and its ultra-high density presents a unique warm and smooth feel, with a steady sound

2. Processing technology

The combination of CNC machining and sheet metal machining is precisely the advantage of Jiayi Technology Co., Ltd. We have a sheet metal machining workshop and CNC quantity lathes, which can simultaneously complete both sheet metal and machining processes, providing customers with one-stop services. Welcome to consult.Contact us.

| Service | Customized OEM / ODM |

| Quotation | According to your drawing (size, material, thickness, processing content and required technology, etc) |

| Materials Available | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

| Surface Treatment | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc |

| Processing | Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding etc |

| Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

| Our Advantages | 1.) 24-hour online service & Quick Quote/Delivery. |

| 2.) 100% QC quality inspection before delivery, and can provide quality inspection form. | |

| 3.) 18+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. | |

| Tolerance丨Surface Roughness | CNC machining: 0.01 minimum, sheet metal fabrication: 0.1 maximum, FTICF: 0.1mm maximum |

| MOQ | 1 |

| Sample Service | Available before bulk order. Sample charge per your design, The sample fee can be deducted from the payment for mass production. |

| Sample lead time | 7-10 days |

| Mass Production Lead Time | 10-30 days per your order quantity |

| Packing | Customers' requirements |

| Place of Origin | China |

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS