- Overview

- Inquiry

- Related Products

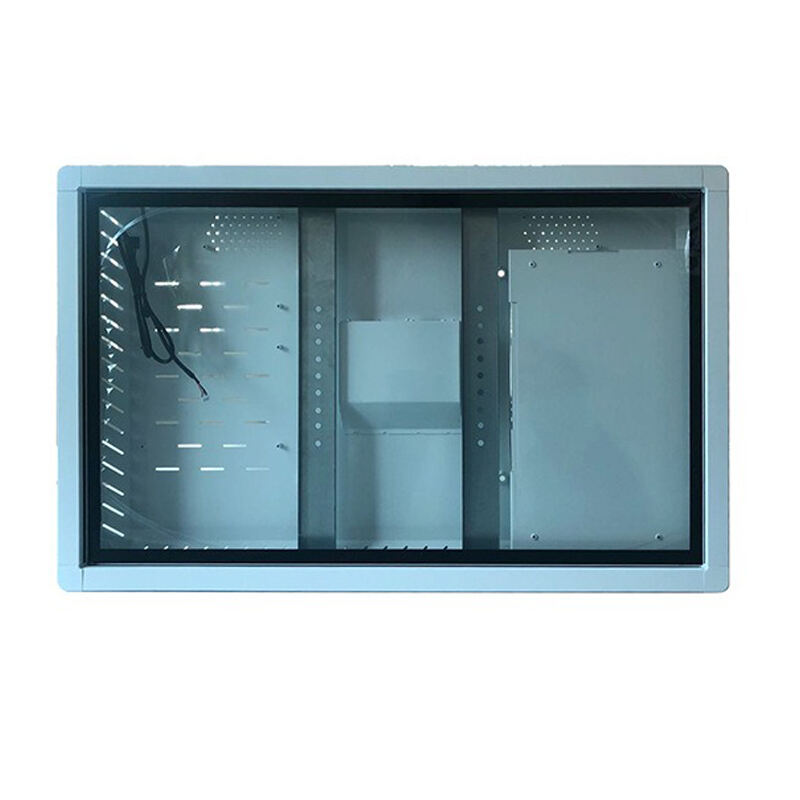

Custom metal casing manufacturer

Shenzhen Jiayi Technology Co., Ltd. is a professional manufacturer of CNC processing and sheet metal processing services. Our sheet metal parts - metal shells - are produced according to customer needs, customized produce according to drawings and samples. With over 10 years of experience, we provide one-stop services from design, drawing, production, assembly, etc. Our services have been recognized by our customers.

Who we are?

JIAYI TECHNOLOGY , its owner, MR Lee have over twenty years experience in the sheet metal fabrication and CNC machining field. All the staffs their expertise is clearly demonstrated in every aspect of the company. Our cutting-edge equipments were imported from Germany including High-power TRUNCA. 6000 watt carbon dioxide laser machine, TRULASER-5030, 6000 watt fiber Rulaaser-3030, CNC bending machine, CNC computer, precision engraving machine, punch machine, grinding machine.

Since its inception in 2017 JIAYI TECHNOLOGY has been a leading manufacturer and supplier of a wide range of super-fine quality Precision Sheet Metal Parts and CNC Machining Parts. All parts are widely used in different industry and manufacturing areas, such as Communication Chassis Cabinet, LED Display Case, Photographic Equipment, Medical Equipment, Unmanned Aerial Vehicle, Intelligent Robot and all kinds of Automation Equipment and so on.

Why choose us?

More than 10 years of profound experience accumulation

Professional and efficient technical team

One stop service

Strong advanced manufacturing capabilities

24-hour online service

Online technical support

FAQ

Q1: How soon can I get your response and quotation?

A1: Usually, you will get our response within 12 hours, not later than 24 hours. Quotation provided within 48 hours.

Q2: Lead time for samples.

A2: Usually 7-10 days, depending on the material, size, and surface treatment.

A3: Usually 14-35 days.

A4: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

A5: Yes, we will not release to the third party without your permission.

A6: We have QC department to control the quality from the beginning of production until goods finish. The quality inspection report will be sent together with each batch of goods.

A7: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products for replacement until your satisfaction.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS