CNC milling: efficient transformation from design to finished product

Design Considerations for Efficient CNC Milling Processes

Material Selection Guidelines for Optimal Machinability

Material selection plays a big role when it comes to CNC milling operations since getting the right stuff makes all the difference between smooth machining and headaches down the line. The physical characteristics matter a lot here too. Think about things like how hard the material is, whether it stretches before breaking, and just how strong it actually is under stress these factors really affect how well the machine works with the material. Take aluminum for example. Machinists love working with aluminum because it cuts so easily and doesn't weigh much, which is why we see it everywhere from airplane components to car parts. Steel tells a different story though. When parts need to hold up against heavy loads or harsh conditions, steel becomes the go to option despite being harder to work with. Many shops stock both materials depending on what their customers need for specific projects.

When looking at how easy materials are to work with, there are industry standards such as AISI and JIS that give these ratings a numerical value, which helps when picking out what goes into production. Take aluminum for example it typically scores around 100% on machinability scales, so no wonder why it remains popular among CNC shops everywhere. Plastics including ABS plastic stand out too because they cut so smoothly during manufacturing processes, hence why many everyday items end up made from them. Getting the material selection right matters a lot for both efficiency and product quality. Materials that machine well simply mean shorter time between parts getting made and less frequent replacement of cutting tools over time.

CAD File Optimization to Reduce Production Complexity

Getting CAD files right makes all the difference when it comes to running smooth CNC machining operations. Most shops prefer working with STEP or IGES files since these play nicely with almost every CAM package out there. Simplifying parts before sending them to the machine shop saves everyone headaches down the line. Designers need to cut back on fancy details that just make toolpaths harder to program or force machinists into doing multiple setups. Take away those extra curves and undercuts whenever possible. Real world experience shows that stripping out unnecessary geometry cuts down both machining time and overall production costs quite substantially.

Parametric design combined with modular parts makes it much easier to tweak products during manufacturing without having to redesign everything from scratch. Real world examples show that when companies streamline their CAD processes, they often cut down on production time by quite a bit. Most manufacturers find that sticking to certain CAD optimization techniques helps them strike a good middle ground between creating complex designs and keeping things simple enough to actually build efficiently.

Balancing Tolerances with Functional Requirements

Getting a handle on engineering tolerances matters a lot when working with CNC milling machines because these specs basically determine whether parts work properly and how much they end up costing to make. When engineers set those tolerance ranges right, the finished product actually fits together and does what it's supposed to do. This becomes super important in fields such as car manufacturing and aircraft production where even small errors can lead to big problems down the line. Take aerospace parts for example – they often need extremely tight tolerances since planes have to withstand tremendous forces during flight. A millimeter off here or there could mean the difference between safe operation and catastrophic failure, which explains why so many aerospace companies invest heavily in precision measurement tools and quality control processes.

The right tolerances depend largely on what material we're working with and exactly how the CNC milled part will be used in practice. Standards like ASME Y14.5 aren't just theoretical documents sitting on engineers' desks they actually provide real guidance for keeping production within spec. When looking at actual cases from sectors like aerospace manufacturing, where even tiny deviations matter a lot, it becomes clear why specifying proper tolerances matters so much. These industries have learned through experience that getting this balance right between making something work properly and not spending too much money on unnecessary precision is critical for staying competitive in their markets.

Implementing Adaptive Clearing Techniques

Using adaptive clearing methods makes CNC machining much better because it speeds up how fast materials get removed while also shortening the time needed for each operation. The technique changes the way tools move around during cutting so they stay at just the right speed for what's being worked on, which helps boost production in almost any milling situation. What really matters is that these adaptive approaches help cut down on tool damage and keep things running smoothly during processing. According to some industry data, shops that switch to adaptive clearing see their productivity jump anywhere from 30 to 40 percent. That explains why so many manufacturers are turning to this approach when trying to optimize their tool paths nowadays.

Trochoidal Milling for Reduced Tool Wear

Trochoidal milling represents a newer technique that actually makes CNC machines work better while wearing down tools less than older milling approaches. The method relies on special toolpaths where cutting forces stay pretty much constant throughout the process, and the chips produced tend to be much thinner. This helps tools last longer before needing replacement. Shops across various industries have started seeing real improvements when they switch to these kinds of paths. One manufacturer reported around 30% savings on individual parts after making the change simply because their tools weren't breaking as often. Beyond just saving money on new tools, this kind of machining slashes overall operating expenses too, giving companies a real edge over competitors who haven't made similar upgrades to their processes.

Leveraging Multi-Axis Machining Capabilities

The shift to multi-axis machining has transformed how manufacturers approach production efficiency, going beyond what traditional 3-axis systems can achieve. These advanced machines, particularly the popular 5-axis models, allow for creating highly detailed components because they move cutting tools across several axes at once. This is especially important in fields that need complicated parts, think about aircraft engines or car transmissions where precision matters most. The aerospace industry provides a clear case study here. One major manufacturer reported cutting down both production time and expenses by around 30% after switching to these newer machines. Industry insiders highlight that multi-axis technology isn't just a trend but a necessity for today's manufacturing landscape. By improving accuracy and giving shops more freedom in how they position workpieces, these systems are changing what's possible in shop floors everywhere, making once impossible designs now feasible within reasonable timelines and budgets.

Material-Specific Design Best Practices

Aluminum vs. Stainless Steel Design Parameters

Getting the hang of how aluminum and stainless steel differ in CNC machining really matters when designing parts. Aluminum stands out because it's light and resists rust pretty well, so engineers often pick it when they need to cut down on weight for things like drones or race cars. Stainless steel tells a different story though. It packs way more punch in terms of strength and lasts longer under stress, which makes it the go-to material for airplane components and car engines that face extreme conditions daily. When designers sit down at their desks, they weigh several things before picking one over the other including what the part needs to do, how strong it has to be, and where it'll end up working. Metallurgists have done tons of testing that gives us numbers on how each material performs, helping manufacturers make smart choices about what goes into production. Take CNC work specifically aluminum cuts faster since it's not as hard as stainless steel, but working with stainless means using tougher tools and going slower through the cutting process.

Managing Thermal Expansion in Precision Parts

When it comes to making precision parts, thermal expansion is something manufacturers really need to watch out for, especially in sectors where exact measurements matter most like aerospace manufacturing and car production. Most metals get bigger when they heat up, which messes with their size and throws off the whole machining operation. That's why smart engineers build this factor right into their designs so finished products still meet those tight tolerances. Engineering studies keep pointing out how important it is to understand how heat affects materials during design stages. Take aluminum versus steel for instance these materials grow at completely different speeds when warmed up. To handle all this, experienced technicians often add expansion joints to accommodate movement or pick special alloys that don't expand so much under normal operating conditions. This becomes even more crucial in equipment that regularly faces big temperature swings throughout its service life.

Surface Treatment Compatibility Considerations

Getting the right surface treatment for materials matters a lot when it comes to making sure CNC machined parts last long enough and follow all the rules they need to. Things like anodizing, plating, and different kinds of coatings have to work well together with whatever material we're dealing with if we want them to perform properly and pass those pesky regulations. Take aluminum for instance it takes anodizing really well and gives that tough outer layer most people look for. Stainless steel on the other hand usually gets passivated instead because this helps fight against rust problems down the road. We've seen plenty of real world situations where companies picked the wrong treatments and ended up with all sorts of headaches coatings flaking away or corrosion starting up unexpectedly, sometimes even causing complete part failures. The good news is there are plenty of industry standards out there acting almost like maps through these tricky compatibility questions. These standards help manufacturers create products that not only look good but actually stand up to what they need to do day after day without falling apart.

Recommended CNC Machining Solutions

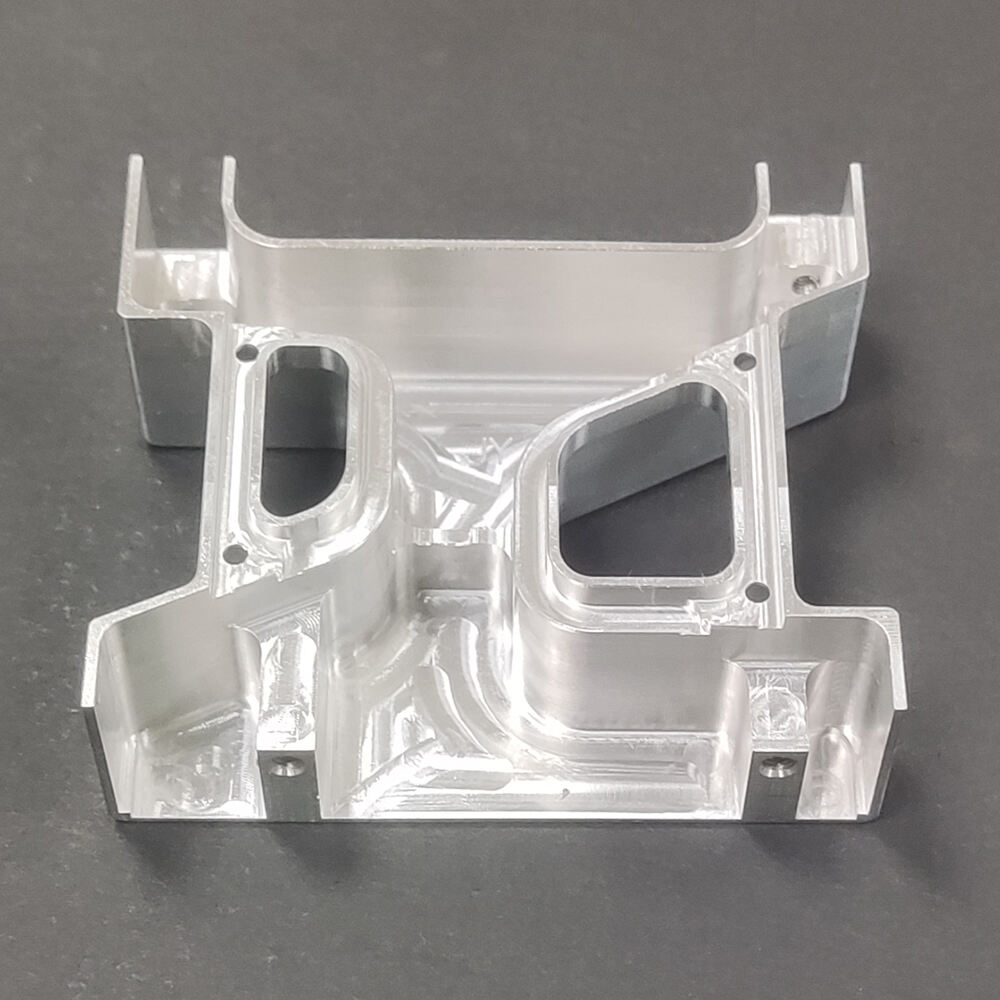

OEM Custom Precision Stainless Steel & Aluminum Components

Original Equipment Manufacturer (OEM) solutions bring something special to the table when it comes to making precise parts out of stainless steel and aluminum for all sorts of industries. What sets them apart is their ability to customize products exactly according to what clients need, which gives companies a real edge compared to off-the-shelf mass produced items. Take aerospace and medical sectors for instance they absolutely rely on custom made components because those industries have extremely high standards for both quality control and exact measurements. Looking at actual cases from customers across different fields shows how OEM approaches cut down on wasted time during production cycles while boosting overall product performance metrics. With advanced machining techniques and specialized tooling at their disposal, OEM shops consistently deliver parts that hit those tough spec requirements, so end users get reliable products they can trust day after day.

High-Tolerance Aluminum Alloy Milling Services

When precision matters most, high tolerance aluminum alloy milling becomes absolutely necessary for many industrial applications. These specialized services are what keeps things running smoothly in fields like aerospace manufacturing and Formula One racing components. Getting those tight tolerances right requires some pretty sophisticated techniques, especially with CNC milling machines capable of hitting 0.01mm accuracy marks consistently. The best machining shops really stand out because they cut down on material waste while still keeping their production lines moving fast. Ask anyone who works with these parts regularly and they'll tell stories about how working with a good mill shop makes all the difference. One auto manufacturer reported saving thousands after switching to a shop that could deliver engine components within microns of specification every single time.

Complex Thin-Wall Structure Machining Capabilities

Working with thin wall structures during machining presents quite a few headaches for machinists. Getting those parts right means paying close attention to every detail so they don't warp or break apart. Most experienced shops will tell you that getting the tool path just right matters a lot, along with figuring out good ways to keep things cool while cutting. The auto and aircraft manufacturing worlds really rely on this kind of work since they need parts that are light but still strong enough to handle serious stress. Modern CNC machines have come a long way too, making it possible to produce all sorts of complicated shapes consistently time after time. Shops that specialize in this stuff often show off their track record with components that meet exacting standards down to the micrometer. What this means practically is that engineers can now design parts that would have been impossible just a few years ago, pushing boundaries in everything from consumer electronics to medical devices.

Quality Assurance & Post-Processing Integration

In-Process Dimensional Verification Methods

Getting those dimensions right while parts are being machined matters a lot when it comes to keeping quality consistent across production runs. Shops commonly rely on things like CNC probing systems and laser scanners to check measurements as components get built instead of waiting until after completion. The ability to spot issues early means workers can tweak settings on the fly before problems become costly mistakes down the line. Some industry studies show that companies adopting these kinds of real time checks often see around a 40 percent drop in defective products coming off their assembly lines. This makes sense because catching errors sooner rather than later just plain saves money and keeps customers happy with reliable end results.

Surface Finishing Options for Different Applications

Getting the right surface finish matters a lot in machining work because it affects how well something functions as well as looks when finished. There are several methods out there including things like polishing surfaces until they're nice and smooth, applying anodizing treatments which help metal parts stand up better against rust and wear, and various kinds of paint jobs that protect surfaces while adding color. The choice between these options really depends on what kind of material we're dealing with and where the finished part will end up working. Take aluminum parts meant for outdoor equipment or machinery used near saltwater environments for example. Most manufacturers would go with anodizing here since it creates a tough layer that resists corrosion much better than other alternatives. This makes sense economically too considering replacement costs down the road.

Final Inspection Protocols for Batch Consistency

Getting final inspections right matters a lot when it comes to keeping batches consistent and meeting all those spec requirements in manufacturing settings. What happens during these checks? Well, inspectors usually do careful visual examinations, take precise dimension readings, and run various function tests to spot anything that doesn't fit within acceptable ranges or shows signs of flaws. Statistical quality control stuff like control charts and sampling strategies plays a really big role here too. These tools help keep quality levels steady from one production batch to the next. Take companies that follow Six Sigma approaches for instance. They've got strict guidelines about how much variation is allowed in their products. This focus on reducing differences between items actually translates into better customer satisfaction rates because people get what they expect every time they receive a product shipment.

Recommended Products

Hot News

-

What is MIM processing method?

2025-11-25

-

Does copper for conductive purposes need surface treatment?

2025-11-21

-

Advantages of CNC machining

2024-01-16

-

What is CNC machining technology?

2024-01-16

-

The development trend of CNC machining

2024-01-16

-

Surface treatment technology in CNC machining: improving product added value

2025-03-20

-

What is the difference between SS316 and SS316L?

2025-11-10

-

Good news -100pcs large mechanical equipment casings have been produced

2025-11-11

-

Surface treatment of stainless steel - powder coating or spray painting

2025-11-13

-

What Role does Sheet Metal Shell Processing Play in Electronic Products?

2025-12-04

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS